System partner in ECM technology

If you think “in ECM”, many things become feasible

that have previously been a problem for you.

Get a quote nowECM technology with KSMA changes your workflow:

There are many manufacturing steps, such as the deburring of workpieces that can be implemented faster and more economically with ECM technology. Growth strategies require competent sparring partners in all areas of the production chain who can react flexibly to market movements with innovations, know-how and the necessary capacities.

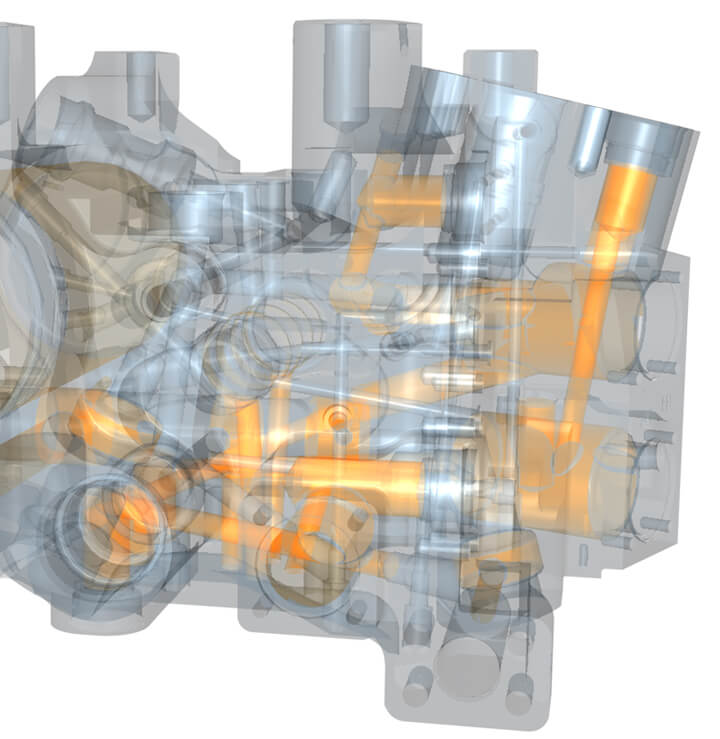

In the ECM process, the workpiece forms the anode and the tool electrode forms the cathode of a direct current circuit. The tool electrode is arranged opposite the positions of the workpiece to be machined. A narrow gap remains between the workpiece and the tool, through which electrolyte flows during machining.

learn more

It is a fact that ECM technology is an economical solution for a wide variety of machining and finishing processes. But it is also a fact that we have undisputed expertise in this area. Process know-how is not the only part of a long-term partnership. For us, goods logistics, quality and innovation also belong in the overall view.

learn more

In some areas, ECM technology represents the technically best, perhaps the only feasible solution for special tasks. Using feasibility and amortization studies, we can tell you when an ECM system or an ECM machine will become profitable in your company. We are interested in embedding directly in your production process.

learn more

Newer? More quickly? Better? New product?

It is always possible and very often the ECM devices are the deciding factor. ECM devices play an important role in the profitability of an ECM system. We also build ECM devices for ECM systems from other manufacturers. If we know the exact parameters, we will always find the best possible solution.

You get the most out of your investment when you train your people well. We know from years of experience that well-trained employees are the key to higher output and shorter downtimes. In our ECM training courses, we ensure that your employees get the best out of their machines. Flexible learning content enables your employees to put what they have learned into practice quickly and directly.

learn moreECM Technology

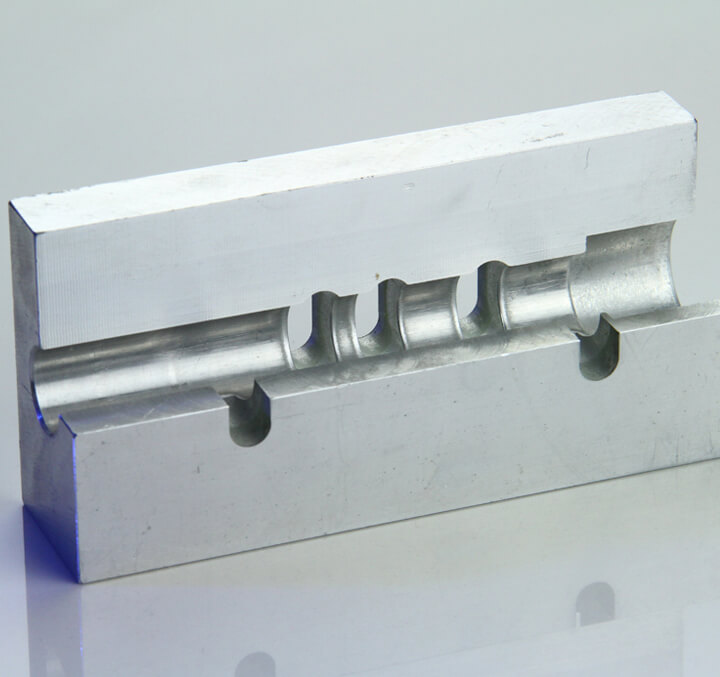

Process description

In the ECM process, the workpiece forms the anode and the tool electrode forms the cathode of a direct current circuit. The tool electrode is arranged opposite the positions of the workpiece to be machined. A narrow gap remains between the workpiece and the tool, through which electrolyte flows during machining.

This electrolyte solution bridges the working gap between the tool electrode and the workpiece and, thanks to its electrical conductivity, enables the flow of current. Due to the effect of the direct current and the electrolyte solution, material on the workpiece is electrochemically decomposed and falls out of the electrolyte solution as hydroxide.

Result: a perfectly deburred workpiece.

- Minimal processing times (suitable for series production)

- Highest personnel-independent processing quality

- Long tool life

- Machining of hard-to-reach burrs and contours

- No thermal or mechanical stress on the components

- One-stop solution in combination with CNC machining

- Suitable for filigree series parts

- Almost any size and shape is editable

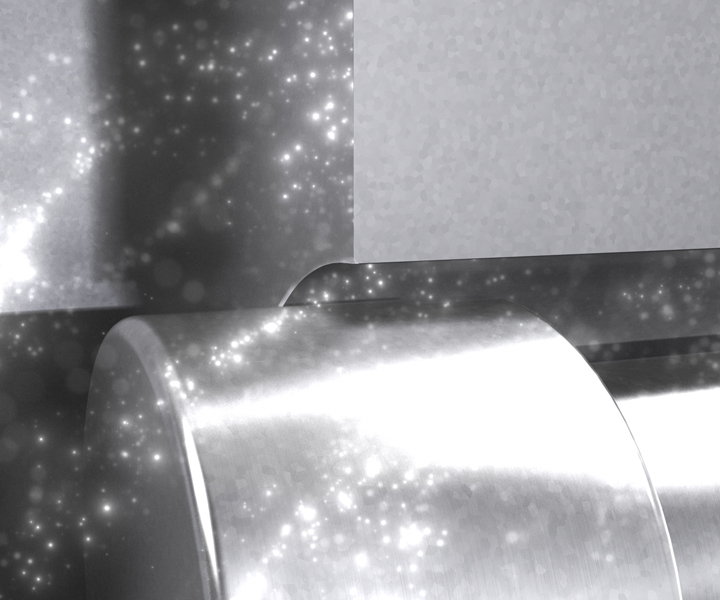

Alternative technology for a variety of solutions

Sometimes the possibilities that ECM technology gives us are not entirely obvious. Sometimes it is the only physically feasible solution for deburring a workpiece or introducing chambers without destroying it. Even after many years of daily use of this technology, we are always surprised at what ingenious solutions we can come up with together with our customers for sometimes extremely complicated tasks.

ECM Contract Processing

KSMA: system partner in ECM contract processing

It is a fact that ECM technology is an economical solution for a wide variety of machining and finishing processes. But it is also a fact that we have undisputed expertise in this area. Process know-how is not the only part of a long-term partnership. For us, goods logistics, quality and innovation also belong in the overall view. From this point of view, we do this job masterfully.

In recent years we have invested in the infrastructure for ECM contract processing in a targeted manner. State-of-the-art systems ensure a high level of efficiency and profitability. KSMA is a reliable partner in the logistics chain to the customer.

ECM Contract Processing

Machinery:

5 x KSMA standard up to 4,000 A.

4 x KSMA double station up to 2,000 A.

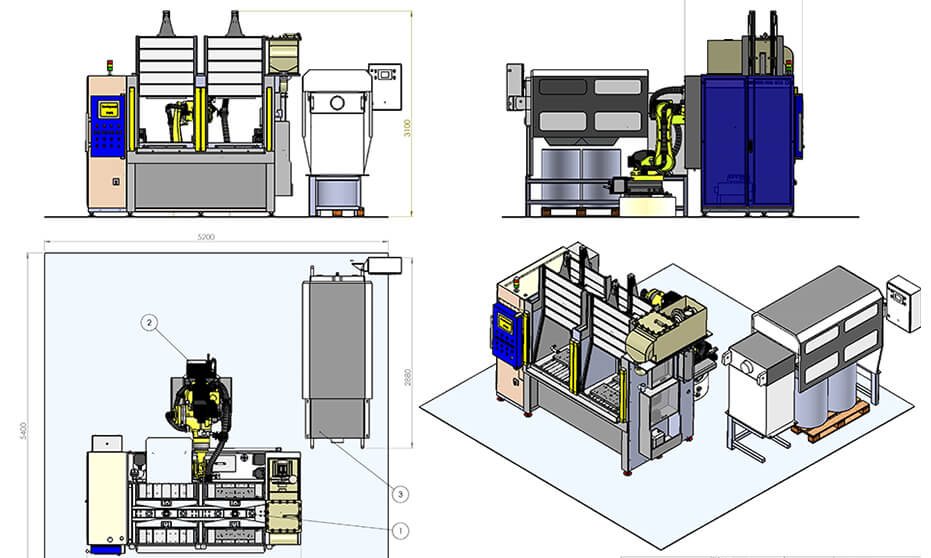

ECM Machine & Plant Construction

ECM machines and systems as part of your production process

In some areas, ECM technology represents the technically best, perhaps also the only feasible solution for special tasks. Using feasibility and amortization studies, we can tell you exactly when an ECM system or an ECM machine will become available profitable in your company. As your partner in ECM plant construction, we are interested in embedding it directly in your production process and ensure that interfaces are created for your tasks.

Complete systems

- Decades of experience with ECM technology

- Inexpensive, economical designs

- Little need for space

- Stable and corrosion-proof construction

- Partly automated, fully automated

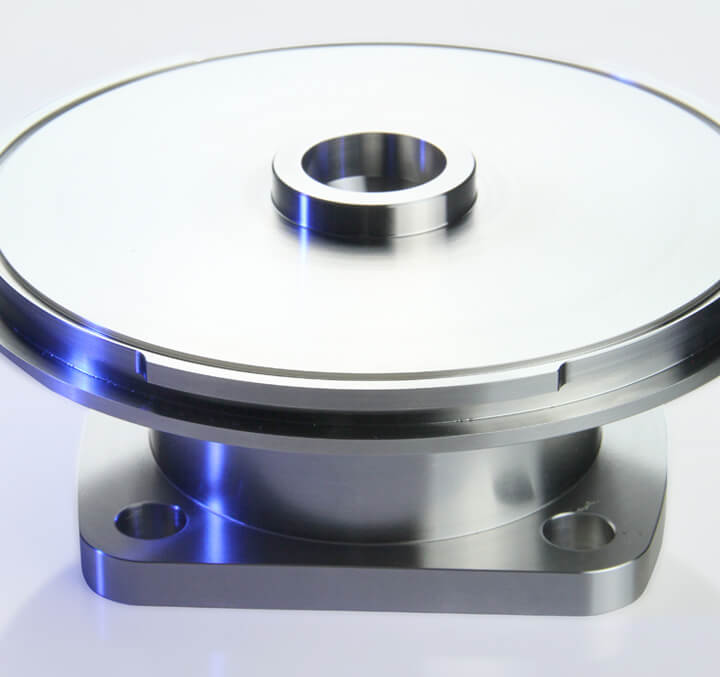

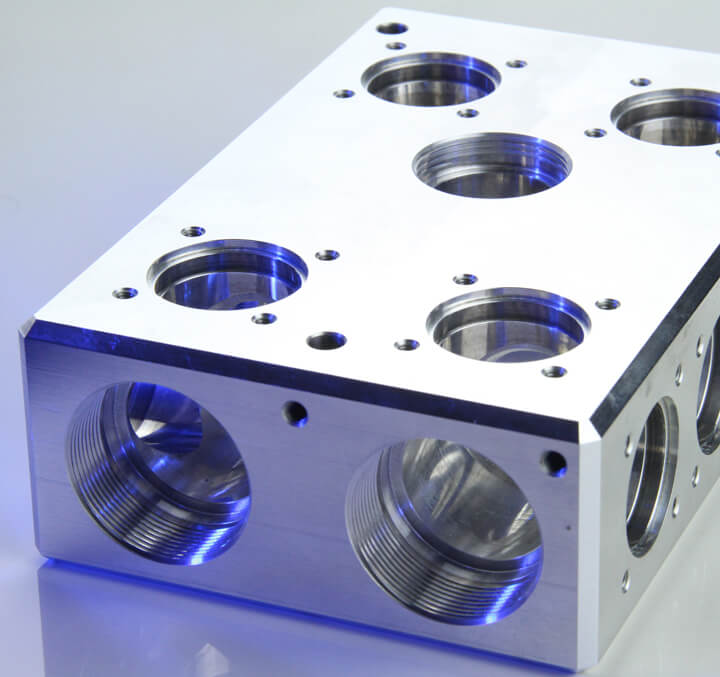

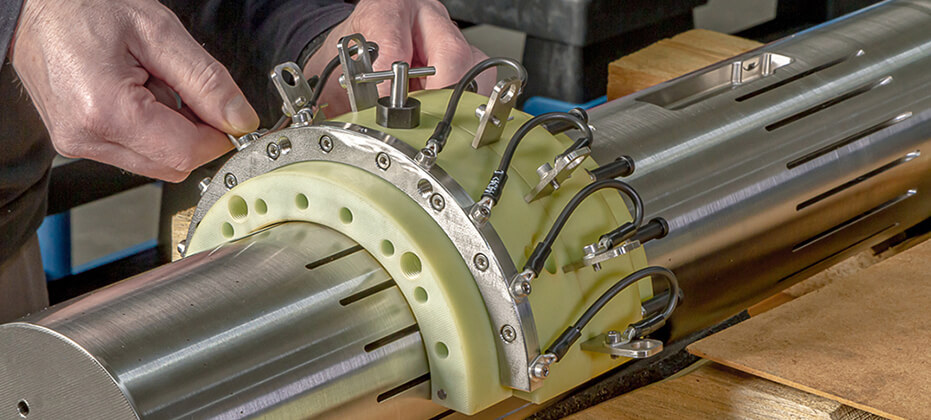

ECM Jig Construction

Modernize old devices or synchronize new workpieces:

Newer? More quickly? Better? New product?

It is always possible and very often the ECM devices are the deciding factor. ECM devices play an important role in the profitability of an ECM system. We also build ECM devices for ECM systems from other manufacturers. If we know the exact parameters, we will always find the best possible solution.

We pay attention to the selection of high-quality materials for our ECM devices in order to be able to achieve a long service life. For decades we have been able to gain experience in this very special field and find increasingly sophisticated solutions to implement the defined and complex task in ECM device construction. We have always succeeded in bringing together the two important criteria of business administration: performance and costs!

Quality is therefore the top priority of our company. Constant quality monitoring processes guarantee our customers first-class products of the highest quality. In 2005 our company was ISO-certified, which of course guarantees our customers and partners an even better cooperation with high quality standards and new developments.

ECM Training

This is how you make your team fit for productive ECM integration into your work processes

You get the most out of your investment when you train your people well. We know from years of experience that well-trained employees are the key to higher output and shorter downtimes. In our ECM training courses, we ensure that your employees get the best out of their machines. Flexible learning content enables your employees to put what they have learned into practice quickly and directly.

Why waste time when we can help you save time? We can develop customer-specific tasks in parallel with you until they are ready for series production. Interface problems are not a problem here. Over the years we have been able to respond to many customer requests and have done very well with this strategy.

Here it has proven to be very practical that we also have the practical side under control. In the KSMA test center, we can convert many ideas directly from the computer data into real solutions and test them directly for feasibility, suitability and cost-effectiveness.

- Higher numbers of deburred workpieces

- Higher quality of the machined parts

- Higher machine availability of the deburring machines